An Off-Season Visit with Commercial Beekeepers

In mid-January, BeeCo took a trip two hours south of our apiary to visit two large scale apiculture operations, Gardner’s Apiaries & Vidalia Apicultural Services. These are large businesses and our hope was to visit them before their busy season started. At each, we were greeted by friendly beekeepers, employees, and business owners who graciously answered our questions and showed us around their facilities in Baxley and Lyons, Georgia.

Gardner’s Apiaries

Our first stop was Gardner’s Apiaries in Baxley, Georgia. We arrived at noon and the office staff was off to lunch, so Chris, an employee of 10 tens years, showed us around. We quickly realized that Chris was not only exceptional at giving a thorough tour, but also widely skilled in almost every aspect of beekeeping. While he is technically the manager of Gardner’s on site woodworking shop and lumber mill, you could see his handiwork and knowledge all over the sprawling complex from the honey processing facility, wax melting shed, honey bottling site, field truck garage, and beekeeping equipment yard.

Gardner’s has around 50 full time employees. They sell queens and 3 lb. packages. Chris shared that he started working last year to manufacture all of the 65,000 boxes that their packages will be sold in this spring. Packages are not the only thing they are making. In fact, they’ve become almost totally independent of having to buy any equipment as they also make their own internal feeders, hives, queen cup, frames, mating nuc boxes, and more.

Employees started work last year to manufacture all 65,000 boxes that their packages will be sold in this spring.

The honey extractor at Gardner’s Apiaries can hold 200 frames of honey.

The honey extractor at Gardner’s Apiaries can hold 200 frames of honey.

We were impressed with how little is wasted. Chris finds ways to repurpose or reuse materials making this operation extremely lean and self-sufficient. They use melted wax collected during honey harvest to coat the inside of the internal feeders they make. Dipping the edges of the feeders into melted wax makes them watertight so they can hold the corn syrup mixed with supplements and electrolytes used to feed their bees in the colder months. After dipping the edges and seams in wax, they’ll also put some inside and move it around to coat the feeder from the inside as well. Melted wax is also used to coat new and recycled hive frames and to make the queen cells that are used during the grafting process. They’ve found that the bees prefer and perform better when they use the wax coated frames and natural wax cups as opposed to the plastic alternatives that are sold by beekeeping equipment companies.

Pallets of internal feeders ready to go at Gardner’s Apiaries.

Internal feeders as shown here are coated with melted wax to seal the inner and outer seams before use in the hives.

Wax blocks in storage at Gardner’s Apiaries. The wax is recycled and used to coat frame foundation, seams of internal feeders, and make queen cups for grafting queens.

A single queen cup made from recycled beeswax that is used in the queen rearing production at Gardner’s Apiaries. They have found that the bees prefer and perform better when they use the wax coated frames and natural wax cups as opposed to the plastic alternatives.

The pile of queen cups at Gardner’s Apiaries resembles a big stash of pasta noodles.

Last but not least was the large natural beehive outside of the lumber shop and honey processing facility. Chris shared that it started about three years ago and has been expanding ever since. He plans to catch the queen in the coming months to breed because feral queens from natural hives have the strongest genetics and most desirable traits, something that Gardner’s and every other beekeeper strives to keep incorporating into their own beeyards and apiaries. Looking up into this natural hive, suspended beautifully and intricately just 10 feet above me, felt like looking into another world. For me, it was a good reminder of just how capable, creative and wonderfully made honey bees are and how lucky I am to get to learn from them.

The natural hive at Gardner’s Apiaries is about three years old. Chris plans to catch the queen to breed because feral queens from natural hives have the strongest genetics and most desirable traits.

The natural hive at Gardner’s Apiaries is about three years old and continues to expand.

The natural hive at Gardner’s Apiaries is about three years old and continues to expand.

Looking up into the natural hive at Gardner’s Apiaries, suspended beautifully and intricately just 10 feet above me, feels like looking into another world. It is a good reminder of just how capable, creative and wonderfully made honey bees are and how lucky we are to get to learn from them.

Vidalia Apicultural Services

Our second visit took us about 30 miles straight north of Baxley to the outskirts of Lyons, Georgia. We walked into the gift shop and headquarters for Vidalia Apicultural Services and met with Heather Davis, Managing Partner and CFO. She graciously agreed to show us around and talk to us more specifically about their queen rearing process, something we would like to continue to improve on back at BeeCo Apiaries.

While smaller in size than Gardner’s, Vidalia Apicultural Services was certainly no less impressive. What started out as mainly a pollination service business is now a thriving apicultural leader in packages and queens. Heather shared with us that when she started beekeeping she had 20 nucs in 2012. Fast forward to today and she’s managing a business of 15 employees selling queens, nucs, packages, and honey products. Heather was the previous Club President of the Altamaha Beekeepers Association.

One thing that impressed us about the set up at her facility was the proximity of the queen grafting room to the breeder colonies, starter colonies, and finisher colonies. All of these are essential components in the queen rearing process and it was interesting to hear about the systems they have in place for achieving maximum and quality production when grafting new queens. From the custom incubators to the wax cups that they also hand make with recycled beeswax, we walked away from our visit with a greater appreciation and understanding that every little detail and step in the process improves the outcome of a quality queen.

Vidalia Apicultural Services has a lovely small gift shop with all sorts of honey and hive products.

At Vidalia Apicultural Services, Heather shows us the peg board they use to make handmade queen cups from recycled beeswax for their queen rearing production.

Frames assembled and ready to go for the busy spring season at Vidalia Apicultural Services in Lyons, Georgia.

Behind the grafting shed and shop, Heather showed us the long line of overwintered nucleus hives. They set them up in late August and continue to feed, monitor, and treat throughout the winter months. Soon they’ll be selling these to local beekeepers looking to restock or build up their own hives. However, their main focus will be on preparing packages to meet the demand of both local and national customers. Some customers are picking up orders that fill an entire tractor trailer. It’s mind blowing when you start to think about the number of bees raised in Georgia and moved across our country to help pollinate food crops. Bees in south Georgia are ending up in such places as Arizona, Wisconsin, and even the Upper Peninsula of Michigan. The importance of these pollinators, and these apicultural businesses in South Georgia, cannot be overstated.

Vidalia Apicultural Services specializes in selling queens, nucs, packages, and honey products.

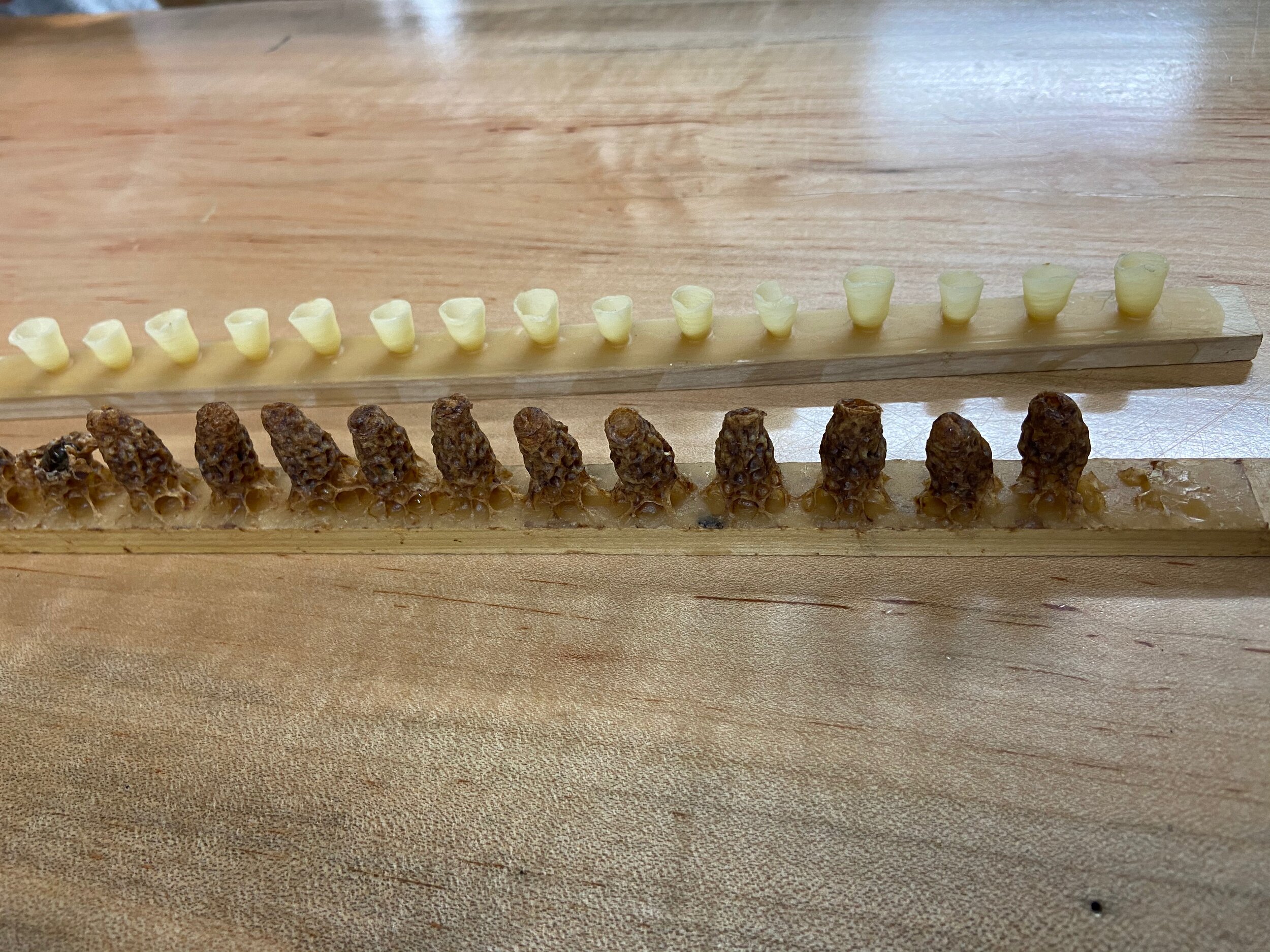

In the gift shop and office, Heather showed us an example bar of queen cups made from recycled beeswax (top of photo) and the fully developed queen cells (bottom of the photo).

Pallets of mating nucs packed and ready for use in the coming weeks as Vidalia Apicultural Services and all south Georgia beekeepers prepare for the busy spring beekeeping season.

We are grateful for both, the honeybees and these two apicultural businesses, and what they do for beekeepers, agriculture, and the ecosystem. The good people at Gardner’s and Vidalia Apicultural Services are friendly and so willing to teach new and experienced beekeepers. We thank them for their time and service.

— BeeCo Apiaries, Mary Lacksen & Katherine Mahlberg